PortMax™

High Flow Access Port System for Rapid Evacuation of HVAC-R Packages

Speed up the lengthy evacuation process of large chiller, industrial & commercial packaged refrigeration systems --- 45% or more reduction in evacuation times compared to commonly used Packed Angle and Ball Valves.

The degassing/dehydration evacuation process is a common bottleneck when manufacturing large refrigeration systems, often taking many hours to complete. The use of small, flow-restrictive packed angle and ball valves is a major contributing factor that slows production Takt time during leak test filling, evacuation, and refrigerant charging processes.

Decrease evacuation time (degas/dehydrate) of large volume refrigerant systems currently processing through packed angle or ball valves.

Reduce Processing Time

Lower Emissions

Next-Gen Refrigerants

Manufacturing, Chemical, Petro-Chemical, Power Plants.

Grocery/Supermarkets, Strip Malls, Office Buildings, Ice Rinks, Server Farms.

Chillers used in Air Conditioning and many Industrial/Laboratory applications.

Food Warehouses, Grocery Super Stores, Pharmaceutical Facilities.

Office & Apartment Buildings, Hotel, College Campus, Multi-Use Facilities. Rapidly evacuate extremely long tubing runs typical in these applications.

Industrial Facilities, Warehouses, and Industrial Kitchens/Food Service Facilities.

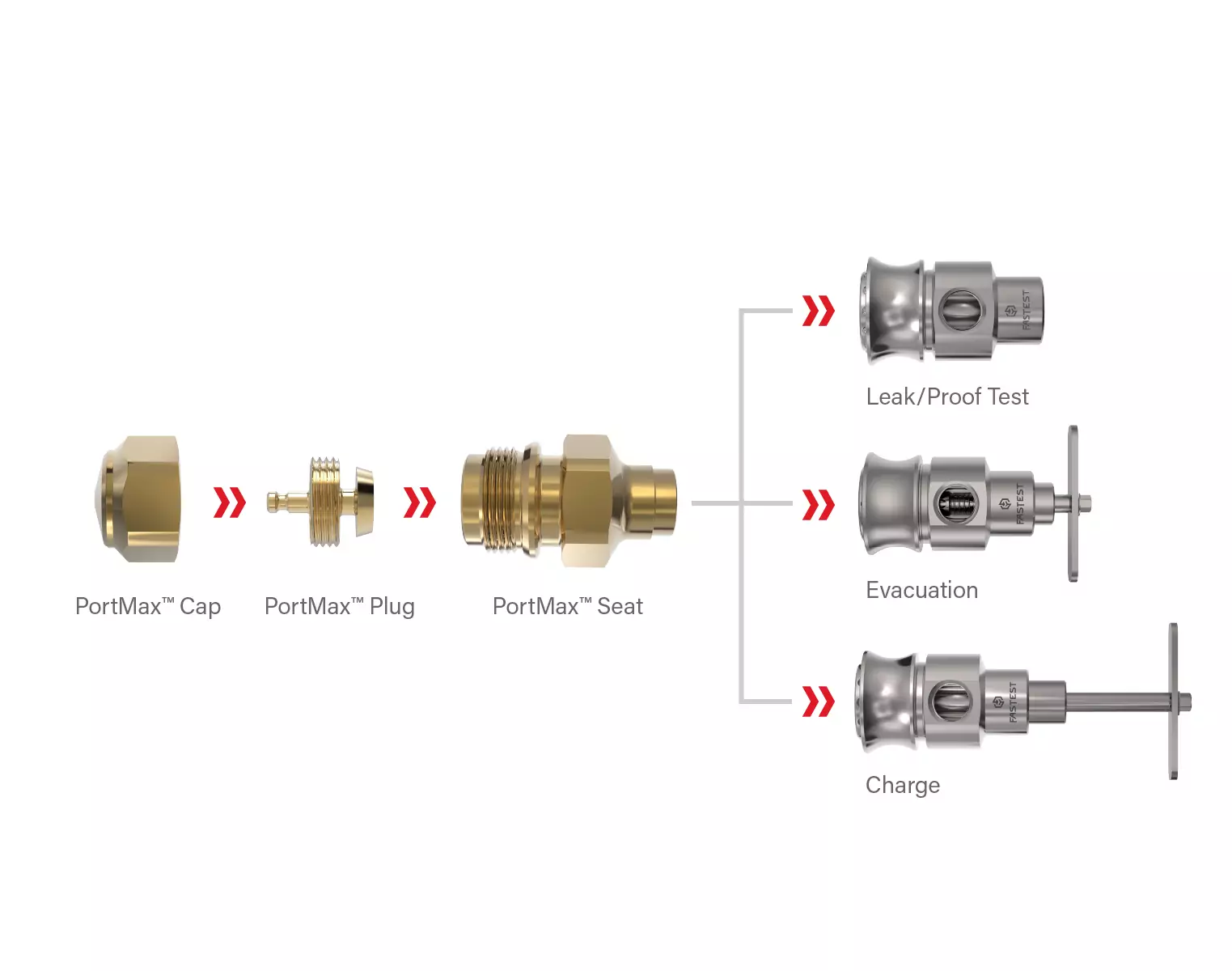

Ball latching connector, no TEE handle mechanism (cannot torque Plug)

Ball latching connector with sliding TEE handle mechanism. Retracts out of flow path for maximum evacuation. Torques Plug to seal system.

Ball latching connector with fixed TEE handle mechanism (eliminates pressure loading). Torques Plug to seal system.

Gain access to the refrigerant system for servicing. Designed to provide installation & service technicians with a single tool that can be used to perform multiple tasks - refrigerant reclaim, leak test, evacuation, charge and replace a PortMax™ access port plug without losing refrigerant charge.

Fully automated evacuation cart for optimized refrigeration system processing with real-time monitoring and data acquisition.

The CoreMax Access Valve & Seat System provides up to five times greater processing flow than common Schrader® type.

The ZeroMax™ access port system is specifically designed to eliminate the need for Process “Stub” Tubes, while adding easy access without sacrificing hermetic metal-to-metal sealing.

With the advantages of FasTest’s leak-tight CoreMax high-flow valve, the CoreMax service valve and single processing tool provide high flow zero emission processing to improve manufacturing efficiency and reduce tooling costs.

Optimized Mobile Evacuation Cart. EvacMax provides rapid and automated evacuation with real-time process monitoring and data acquisition. Technicians now have the ability to set testing targets, start the evacuation and walk away.

Fill out this form to get in contact with a FasTest Connection Expert.