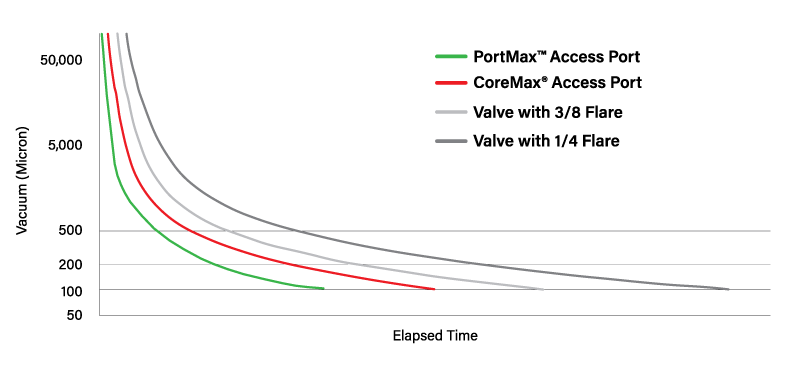

Cut Evacuation Times in Half.

Fully automated evacuation cart for optimized refrigeration system processing with real-time monitoring and data acquisition.

Fully automated evacuation cart for optimized refrigeration system processing with real-time monitoring and data acquisition.

Integrated with ICON™ technology, technicians now have the ability to set testing targets, start the evacuation and walk away.

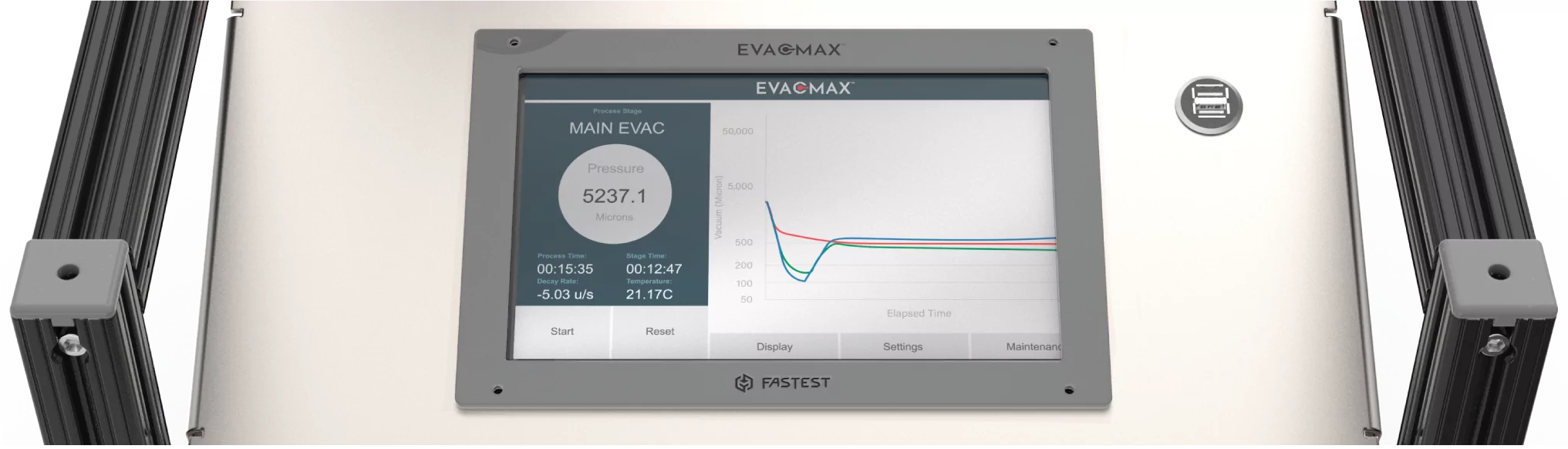

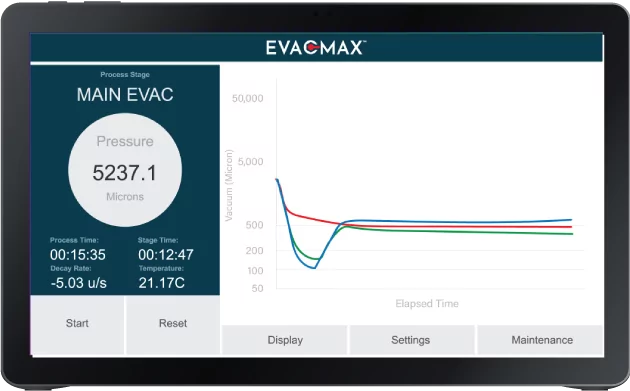

EvacMax™ evacuates the system while displaying progress in real-time on the user interface, tracking up to 6 vacuum gauges simultaneously. If the target vacuum set point is reached, it automatically begins a vacuum decay test. If the test fails, EvacMax will rerun and attempt to pass the test. The entire process is recorded to a downloadable data file for record keeping and analysis. The result is hands-free, fast system evacuation, often in half the time of current evacuation methods.

Drastically improve evacuation times.

Real-time process monitoring and downloadable data logging.

Hands-free automated evacuation and vacuum decay testing.

Quickly identify problems and optimize your evacuation process.

Manufacturing, Chemical, Petro-Chemical, Power Plants.

Grocery/Supermarkets, Strip Malls, Office Buildings, Ice Rinks, Server Farms.

Medical/Hospital Facilities, Laboratories, Schools.

Food Warehouses, Grocery Super Stores, Pharmaceutical Facilities.

Office & Apartment Buildings, Hotel, College Campus, Multi-Use Facilities. Rapidly evacuate extremely long tubing runs typical in these applications.

Industrial Facilities, Warehouses, and Industrial Kitchens/Food Service Facilities.

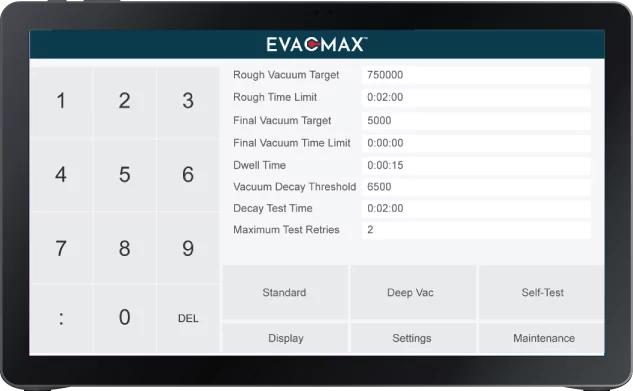

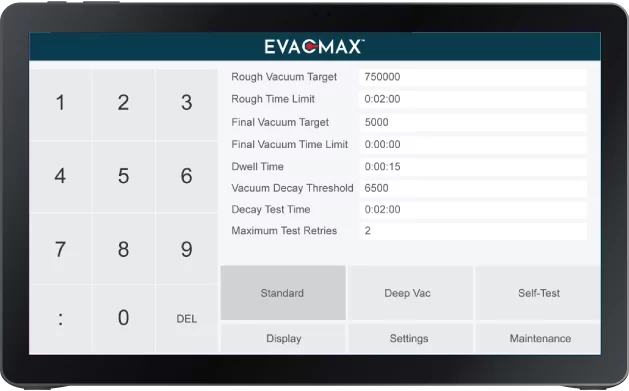

Set target vacuum, vacuum decay and number of retry parameters. EvacMax can save up to 6 evacuation profiles for quick access.

Start the evacuation.

EvacMax™ will do the rest.

If the system fails the vacuum decay test: