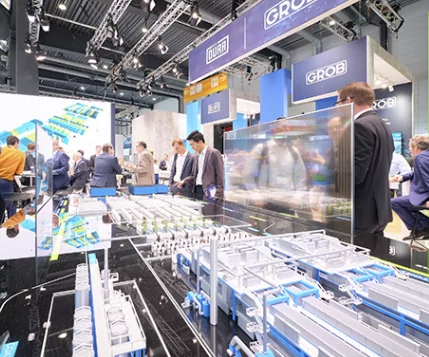

Battery Show Europe 2025

Improve Speed & Accuracy of Battery Pack Leak Testing

A high quality, repeatable leak test is crucial for high volume EV battery production. Even a small leak under the electrical headers or cooling ports could allow contamination or condensation into the battery pack itself, resulting in catastrophic damage to the most expensive component on any EV.

The electrical header connections mounted on EV batteries are generally brightly colored, glass filled polymers. Electrical header port sealing requirements have presented a significant challenge for EV engineers trying to achieve a leak tight seal with consistent compression around the port perimeter, particularly where small radius corners are present. While traditional o-ring seals are designed to effectively seal circular openings, EV battery pack electric header connections are often square, rectangular, or oval.

To overcome this challenge, FasTest partnered with EV industry leaders to create a superior sealing, longer-lasting solution. Our new EHL family of leak test connectors incorporate a proprietary actuation and seal design that provides a consistent seal around the entire perimeter of non-circular ports, in addition to the durability, accuracy, and consistency demanded by engineers working on high volume EV production.

Manual Hand-Operated Connectors for Battery Pack Leak Testing

Manual Connections to EHL Electrical Headers

Manual Connections to VDA Ports

Manual Connections to DGV Ports

Pneumatic Connectors for Automated Battery Pack Leak Testing

Automated Connections to EHL Electrical Headers

Automated Connections to VDA Ports

Automated Connections to DGV Ports

Additional Resources

Contact a Battery Pack Connection Expert