Customer

A leading Detroit based manufacturer of engines.

Application

A high-volume engine leak test station.

Challenge

The plant produces about 200 engines per day and experienced false failures on 20-30% of the leak tests and poor first pass yield rates.

Project Goals

- Eliminate the 20-30% false failure rate

- Improve safety and ergonomics

- Improve throughput and engines per shift

- Connector must be automation enabled

Solution

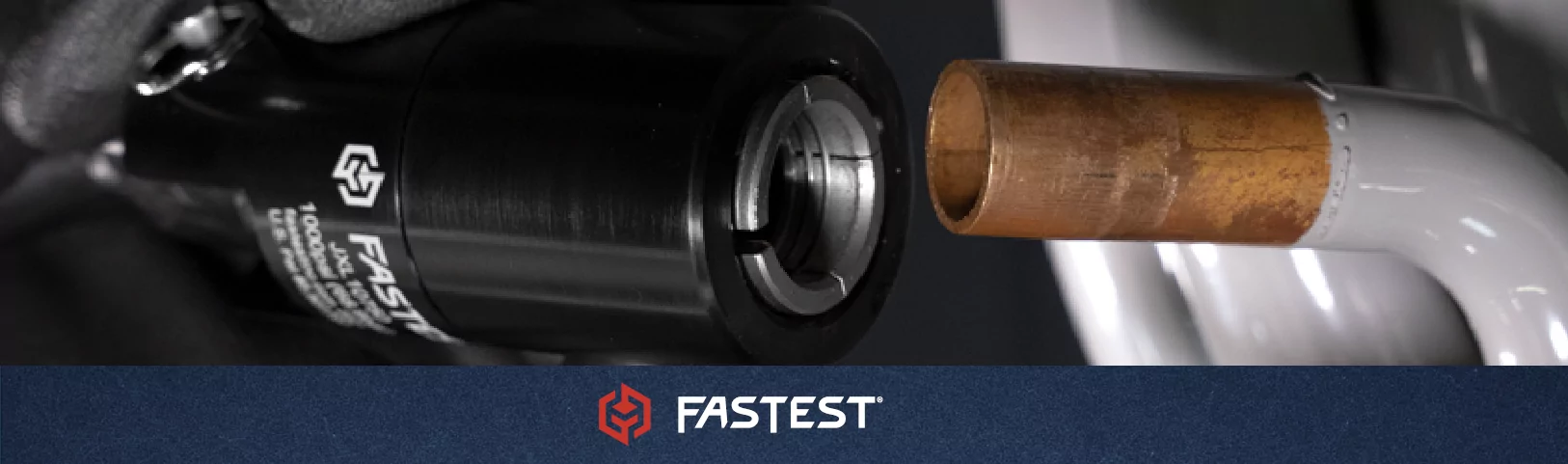

The FasTest engineering team worked directly with the customer to develop a pneumatic JX product family connector.

Results

The JX connector significantly enhanced customer operations by offering a user-friendly interface for both automated and manual processes. It bolstered test safety and represented a substantial ergonomic advancement over previous methods. Crucially, the JX connector yielded substantial cost savings, with customers saving tens of thousands of dollars per shift post-implementation. FasTest’s combination of expert engineering and strong customer relationships transformed a production challenge into a mutually beneficial outcome. By collaborating with FasTest, the customer achieved an estimated $80,000 in savings per shift by reducing false failure rates from 2030%. Additionally, enhancements in setup and takedown times, test precision, and the durability of the connection tool further boosted production and overall procedural efficiency.